Rapid Bay is one of South Australia’s top destinations on the Fleurieu Peninsula, best known for its jetties, fishing, scuba diving, camping and beach caves. Every year around summertime, you will find hundreds of influencers uploading selfies on the beach, families camping in the caravan park and recreational anglers on the jetty. But, to my surprise, Rapid Bay played a more significant role in the establishment of Adelaide than most people would expect, from colonisation to the Quarry that provided essential resources for the war effort. P.S. I would like to acknowledge my primary source, “Rapid Bay…Before we forget” by Des Lord, available at the Yankallilla Visitor Centre. Honestly, this is a hidden gem and one of my favourite South Australian history books; go pick yourself up a copy before they are gone.

When Colonel William Light was tasked with surveying the new colony of South Australia, the Colonization Commission assigned him the ship Rapid, which would be the inspiration for the name “Rapid Bay.” The survey party set up a base camp on Kangaroo Island and would explore the Gulf of St Vincent for a suitable location for a settlement. When Light landed at what would soon be named Rapid Bay on 8th September 1836, he described the area in his journal as a ‘little paradise.’ Rapid Bay was almost chosen as the capital of the settlement of South Australia because it had “a good harbour, a good source of freshwater, expanses of arable land an abundant supply of building materials.” However, the colonists scrapped this idea when they later found the more suitable location of Holdfast Bay. Rapid Bay was continually used as a camp for early settlers in the Fleurieu Peninsula region. For almost 100 years, the area was used for large farming stations and small mining claims, such as the “Yattogolinga”, “The Wheal Collin”, and the ” Olivaster” Mines.

Colonel Light’s surveying ship Rapid in rough seas at Rapid Bay – Source: State Library SA

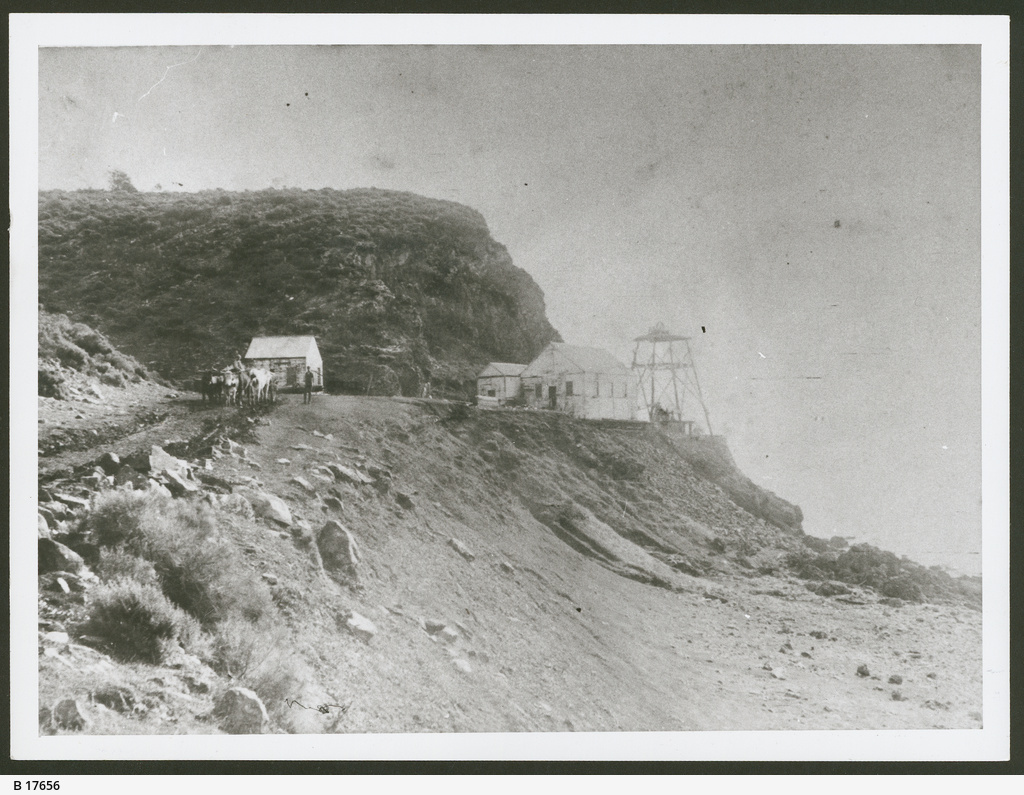

Wheal Coglin Copper Mine – Source: State Library SA

On 11th November 1925, When the Superintendent of Broken Hill Proprietary Company (BHP) found a large amount of limestone on the surface of the hills to the west of the Bay, this set the wheels in motion to transform Rapid Bay from a small farming community into a model township. BHP spent several years negotiating to acquire the land from the farming families, motivated by the fact that the limestone would be incredibly cheap to produce and transport right on the coast. The establishment of the Quarry began in 1940, when World War 2 had just started, and there was increased demand for steel production. Limestone was a much-needed ingredient for steel production in Australia, and it was urgently needed for the war effort. Most of the quarry workers were recruited from the district; some lived onsite, and others walked across the hills to work each day. However, very few workers could commute by vehicles due to the wartime petrol restrictions.

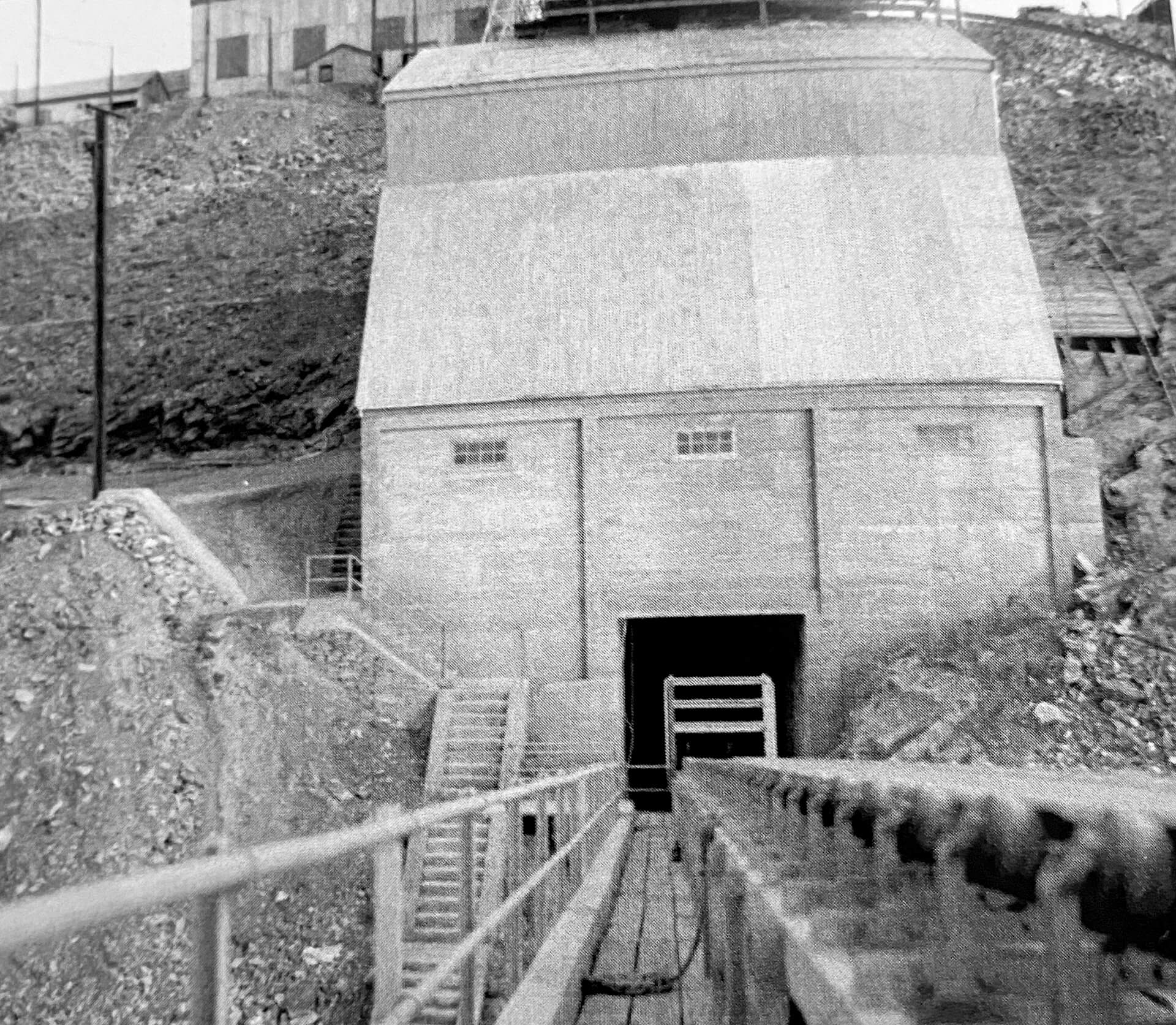

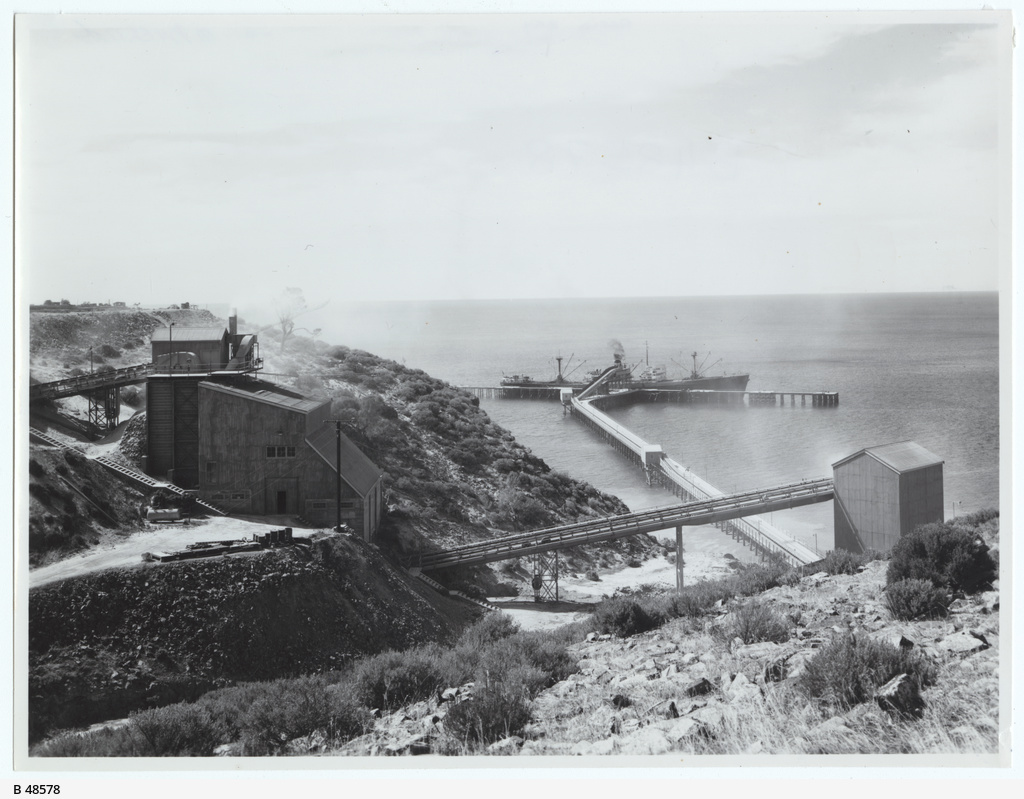

Construction began in mid-1940. A road was dug into the hillside, past the old copper mines to the level of the proposed quarry floor. The machine shop was constructed first (which can still be seen standing at the top of the hill). This was important for creating all of the building materials and assembling the electric shovels for the Quarry. The primary crusher was built on the quarry floor. Then, each other component were built descending the hill connected by conveyors, such as the secondary crusher, screening tower and gullet. The limestone would be dropped into the primary crusher and descend the slope through these different processes until it reached seal level, transported along the jetty onto ships.

1941 looking down on the construction of the secondary crusher. Photo by Dorrie Modra – Source: Des Lord

1942 The ( Ruston Bucyrus Eire 100RB ) electric shovel used in the quarry – Source: Des Lord

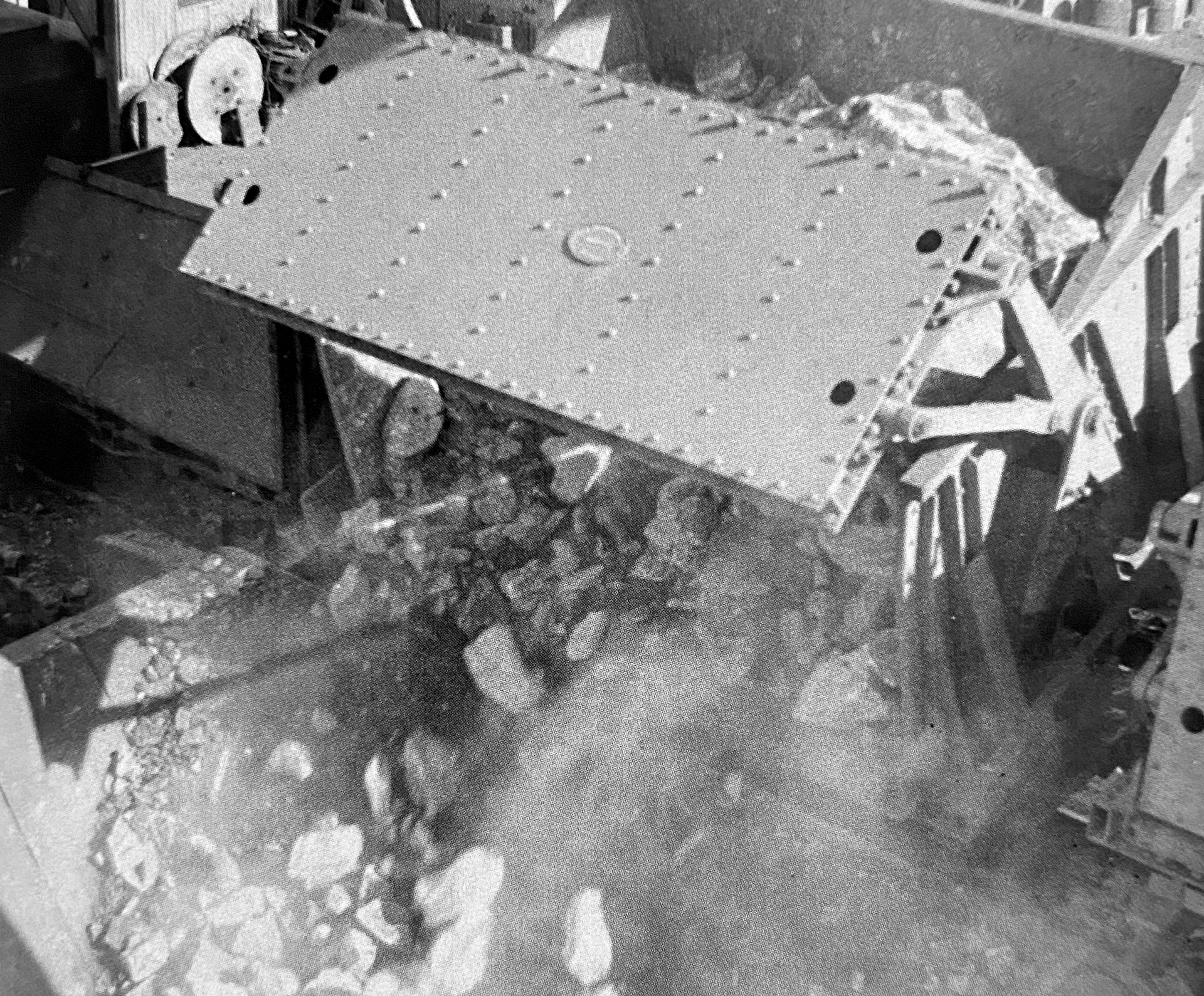

The open side of an ore carriage offloading into the primary crusher – Source:Des Lord

Front view of the secondary crusher building: Photo by steel cap gallery. Tanderra craft village. Source: Des Lord

If you explore the Rapid Bay quarry, you can see the two old Magazines where the explosives were stored; these structures are reinforced concrete built into the hillside with huge metal doors. Explosives would be collected from the railway at Willunga in large metal containers loaded onto a truck for transport. The sticks of explosives were packed in plastic inside a wooden box which would be safely put into the metal container.

1955 The explosives truck: Photo by steel cap gallery. Tanderra craft village. Source: Des Lord

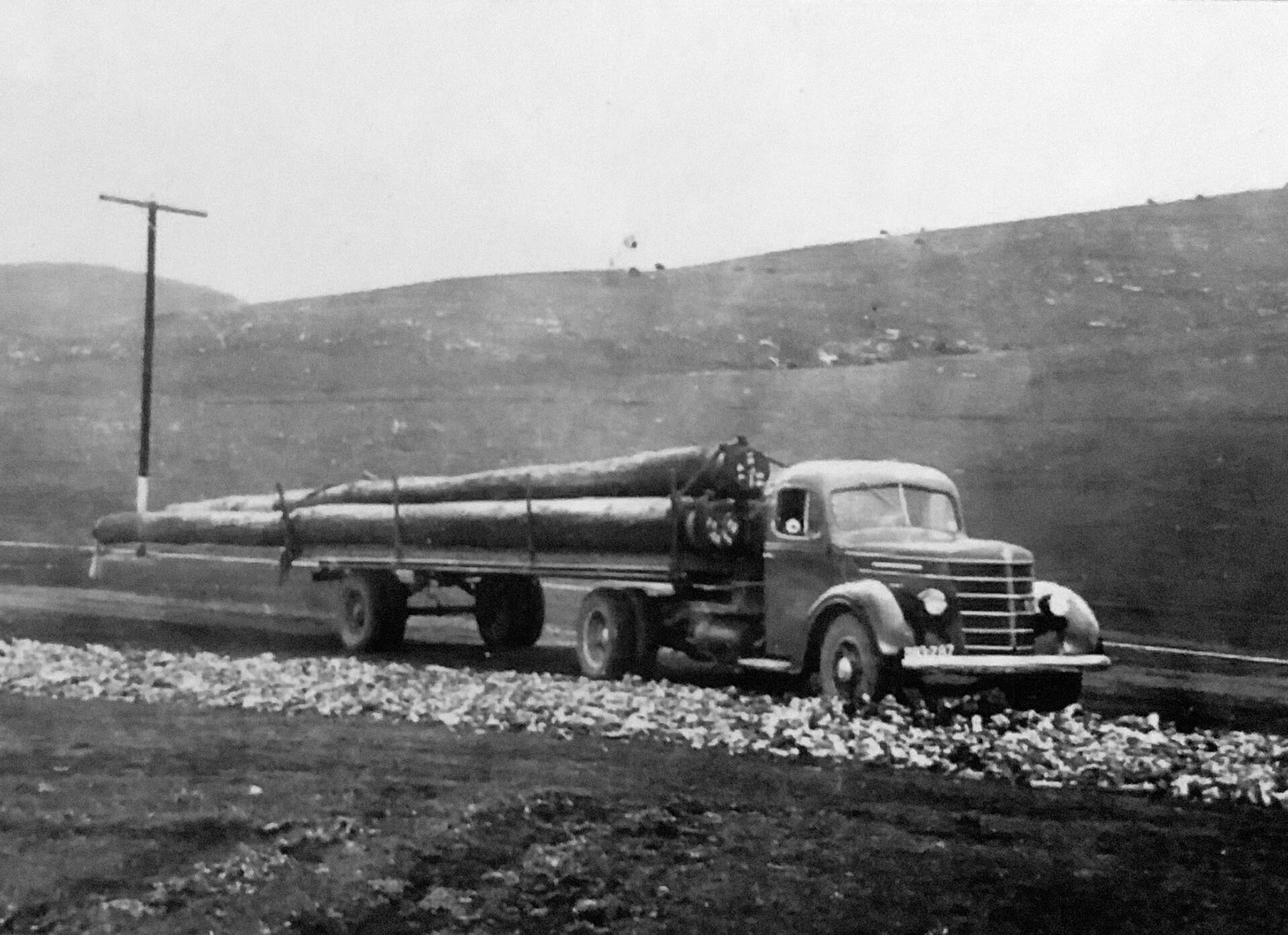

The construction of the jetty was quite an effort for the time; piles from the jetty were unloaded at Port Adelaide and transported to Rapid bay via trucks. Due to the deep water the jetty was in, these piles would be very long, and the trucks would need to navigate the harsh and steep terrain. Some of the unsealed roads on the 1940’s Fleurieu Peninsula were extremely treacherous, often narrow, with tight bends and sheer drops into gullies below. Back in those days, a round trip from Port Adelaide to Rapid Bay took approximately twelve hours. A steam-driven pile driver was custom built for the jetty construction, which would lift piles into position and drive them into the seabed. Unfortunately, during construction, a boilermaker welding the framework of the jetty connections went missing, and his body was never recovered. The only trace that was ever found was his ruler on the seafloor below.

September 1940, Steam-driven pile driver in action. Photograph by Rapid Bay School. Source: Des Lord

Trucks arriving with jetty piles which were up to 90 feet long. Trucks carried 5 piles per load.

Source: Des Lord

Rapid Bay jetty in 2021 – Photo by Jacko Flies

Rapid Bay jetty in 2021 – Photo by Jacko Flies

Rapid Bay jetty in 2021 – Photo by Jacko Flies

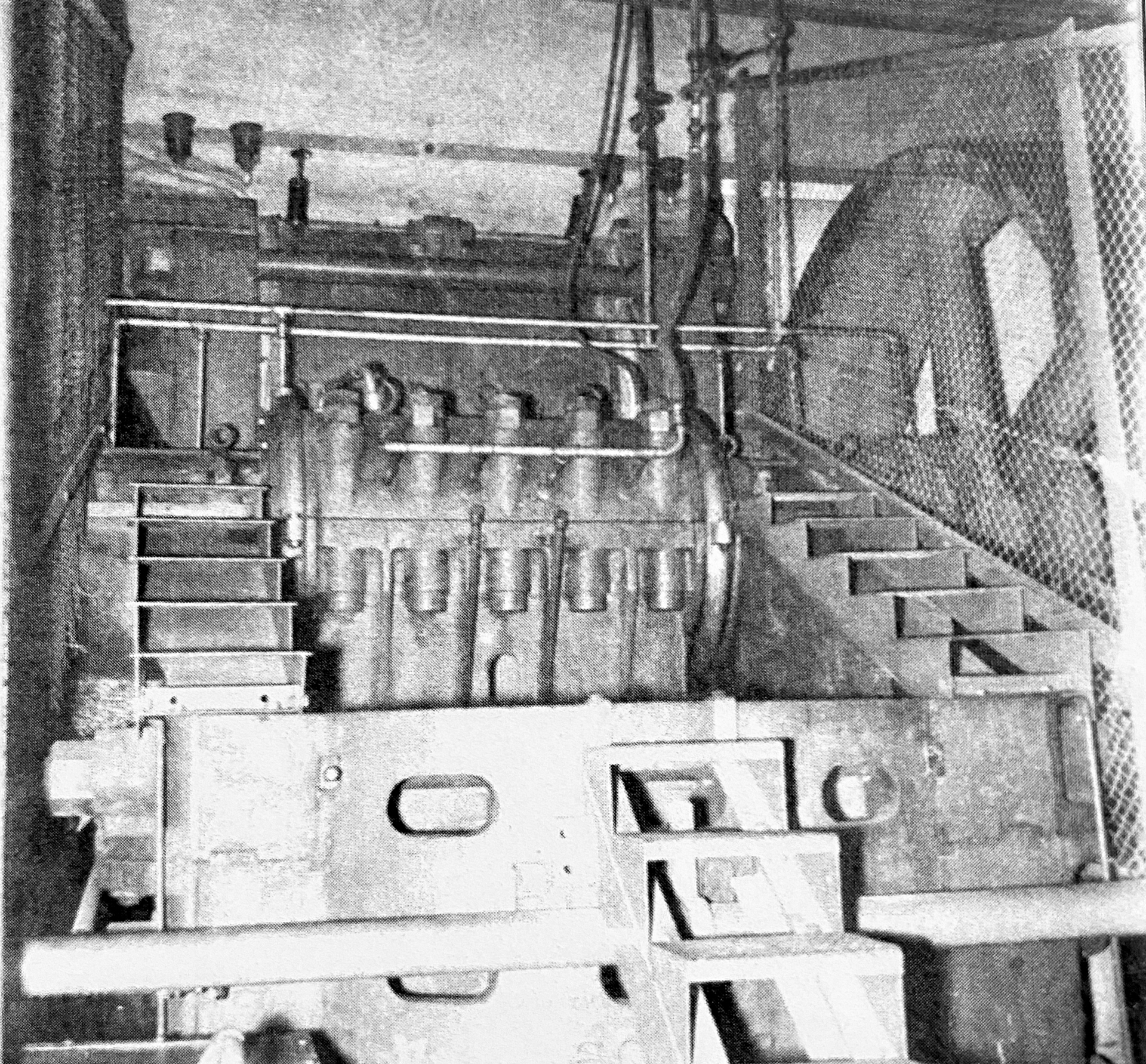

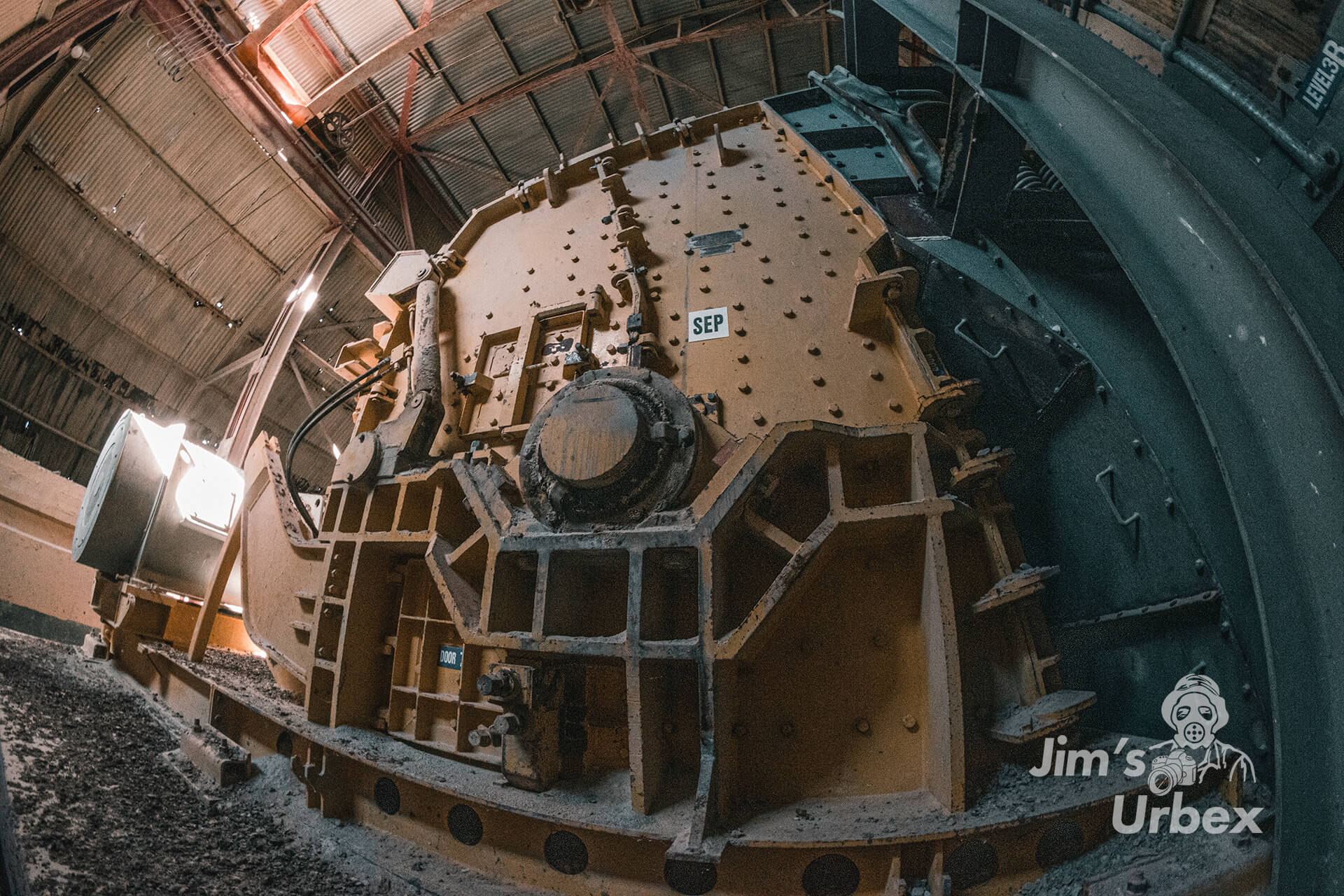

On August 1942, the quarry infrastructure was complete and ready for limestone production. The primary crusher building had a 299hp Vickers Ruwolt Jaw crusher, the largest in Australia at the time and was able to handle huge stones. The secondary crusher housed two Ruwolt jaw crushers, similar to the primary crusher but much smaller. When Adelaide Brighton Cement took over the Quarry in 1982, the primary crusher remained the same. However, the secondary crusher didn’t crush the stone small enough, so ABC removed both original secondary crushers and added a fully automatic SMB vertical shaft impact crusher, weighing 150 tons. This crusher remains and operates with six metal bars spinning within the impactor as it is fed stone via the conveyor belt. The stone is either smashed up by the bars or broken up while impacted against the inner sides.

The original Vickers Ruwolt Jaw Crusher. Source: Des Lord

How a horizontal shaft impactor works: Source

When the crushed material reached the screening tower, the larger stone was separated from the waste gravel and transported into the distributor. At this part of the process, the worker could stop the bins wherever they wanted the stone to be stored. The rock would then be transferred through the gullet on a conveyor belt onto the jetty, ready for shipping. In the ’90s, the jetty was handed over to the government, leaving it in disrepair and eventually collapsing into the ocean. In 2001 the gullet and screening tower was demolished. Only one man is the sole employee of Rapid Bay; he is employed part-time and responsible for the upkeep of the ABC side of town. The ABC side of town is complete with a general store and 1940’s miner’s cottages; some may call it a ghost town. However, if you visit Rapid Bay today, you will see that their caretaker maintains them well and gives the old buildings the love they deserve.

gullet and screening tower being demolished 2001. Source: Des Lord

gullet and screening tower being demolished 2001. Source: Des Lord

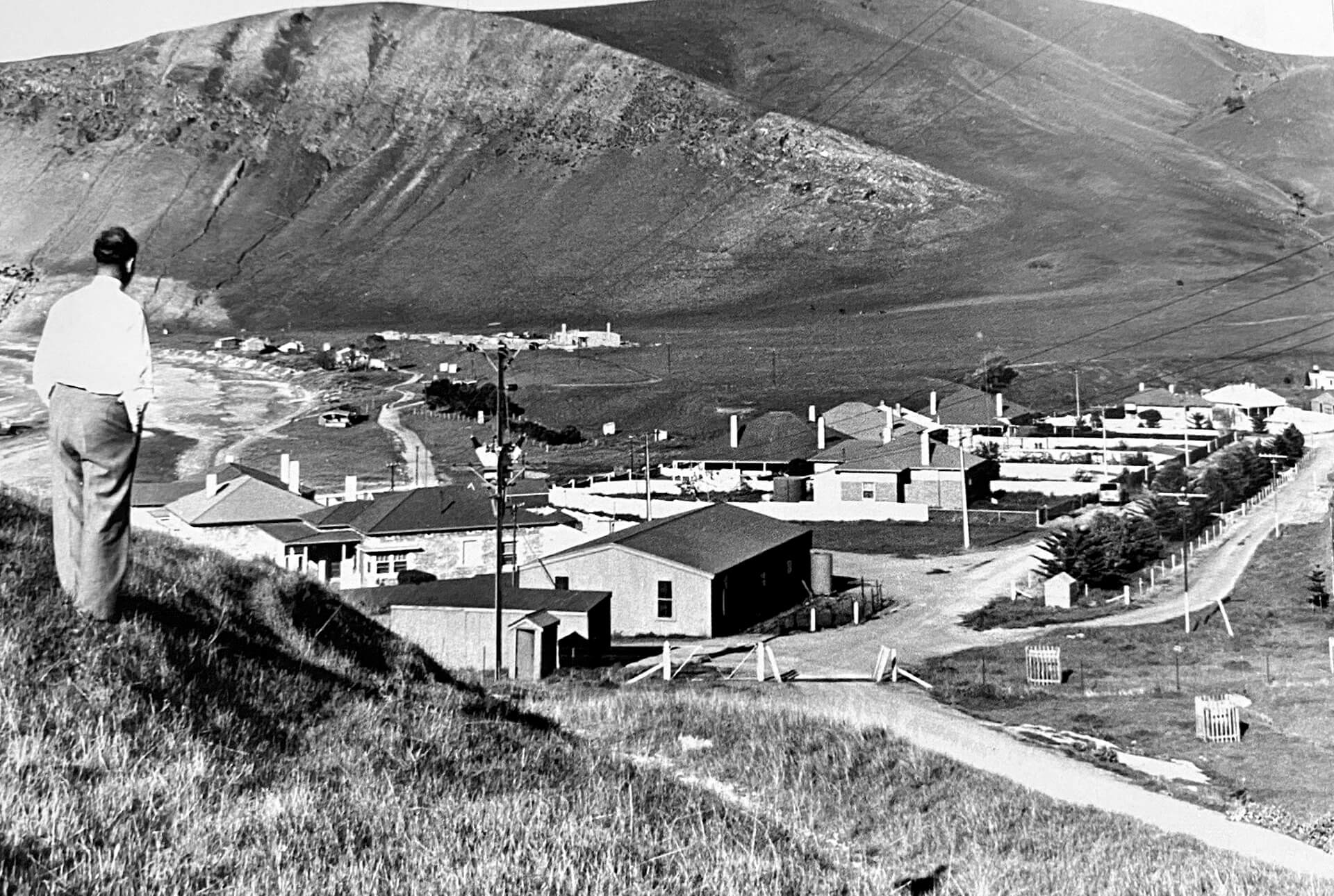

Mining accommodation 1940’s. Source: Des Lord

The same mining accommodation, empty and disused 2020. Source

Given the extensive history of the Quarry, it is surprising there were hardly any accidents recorded. However, I did discover an exciting story of a near miss that happened soon after quarry production had begun. Vic Hogan was one of the bin attendants on the third level of the Quarry, sifting through material from the sides of the bins. On this occasion, he lost his balance and fell 10-15 meters into the waste compartments of the bins. Vic was injured; however, other workers noticed, raised the alarm and devised a rescue plan. An empty drum barrel was lowered onto him with ropes to prevent more rocks from being dropped on top of him. Unfortunately, the rescue didn’t go to plan, and Vic slid down the waste funnel near the bottom of the bins. Luckily, someone opened the chute below the containers. At this point, Vic slid below the dust and dirt. Only moments later, his legs came out of the narrow opening in the chute, and he was able to be pulled free. Vic Hogan has some great luck that day, surviving the ordeal with only a broken leg.

Rapid Bay 1940

Today, most of the Quarry still stands, the main buildings are locked up tight – protecting some of the relics from Rapid Bay’s History. I would recommend a trip to Rapid Bay if anyone is visiting the Fleurieu Peninsula. If you can pick up a copy of “Rapid Bay…Before we forget” by Des Lord” from the Yankalilla visitor centre, you won’t regret it – there is much more info that I didn’t include in my short summary.

– Jim

Rapid Bay also had a 3′-6″ electric railway with Metropolitan Vickers locomotives. These locos carried the limestone round the site. One was donated to the Australian Electric Transport Museum at St Kilda in complete form, with everything needed to run again. The AETM donated it later to the National Rail Museum at Port Dock.

https://nrm.org.au/collections/31-search-our-collections/164-locomotive-e1

Wow, very interesting. Thanks for sharing! I’m keen to go check it out now